- Textile Effects

- /

- SUPER SYSTEMS+

- /

- Bottom Weights (PES/CO)

Bottom Weights

Achieve valued effects like durable colors, easy care and non-iron finishes, abrasion resistance and stain protection. Prioritize resource savings and operational excellence. Ensure compliance with current or anticipated chemical restrictions.

Super Systems+

We believe that we can reduce the environmental impact for the planet and people by improving resource savings in manufacturing and consumer use, adopting cleaner chemistries and enhancing durability of the finishing effects and colors.

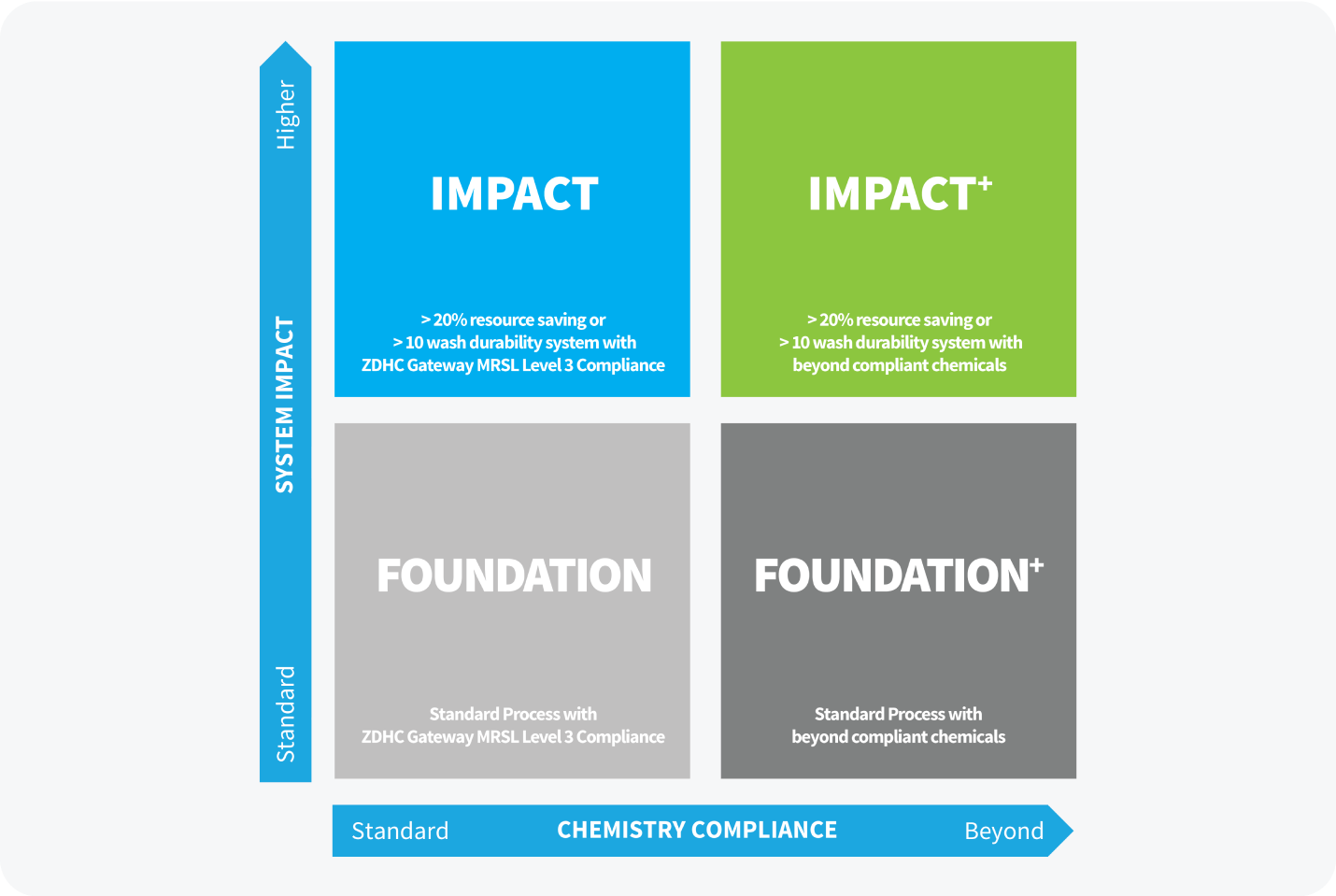

Organized into four quadrants Foundation, Foundation+, Impact and Impact+. The Impact Matrix addresses the key challenges facing the textile industry and guides you in making informed decisions about using cleaner chemistries, resource saving solutions in processing, improved durability in consumer use or a combination of all.

Our Super Systems+ is a comprehensive tool that guides you to achieve your sustainability goals without compromise.

Features

Available Super Systems+ levels

We’re sorry, but there are no results for this configuration.

Impact

Garment savings

Compared to Foundation

7.4L vs 13.4L of water

0.27kwH vs 0.47 kwH of electricity

424g vs 776g of carbon emission

Cost Calculated with 2.5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.075 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

CONTINUOUS PRETREATMENT SYSTEM

- Product selection for highest requirements in terms of water retention (absorbency) and whiteness

- Fully phosphorous-free product selection

- Bactosol HPA for flexible application (Pad Steam, immersion) and efficient starch degradation

- Prestogen SIFA for highest base whiteness in combination with OBA

- Invatex SA with excellent dispersing and heavy metal chelating power

TERASIL® W and NOVACRON® EC

- Highest Production Efficiency

- Shortest Processing time with minimum environmental impact

- Highest Resource Savings

- Highly recommended for 40 0C Wash fastness

- Excellent dry heat fastness

- Very good CEL reservation

- Very Good stability to reduction, leading to excellent shade reproducibility

- High fastness to multiple Home Laundering

Compared to Foundation

7.4L vs 13.4L of water

0.27kwH vs 0.47 kwH of electricity

424g vs 776g of carbon emission

Cost Calculated with 2.5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.075 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

CONTINUOUS PRETREATMENT SYSTEM

- Product selection for highest requirements in terms of water retention (absorbency) and whiteness

- Fully phosphorous-free product selection

- Bactosol HPA for flexible application (Pad Steam, immersion) and efficient starch degradation

- Prestogen SIFA for highest base whiteness in combination with OBA

- Invatex SA with excellent dispersing and heavy metal chelating power

TERASIL® W and NOVACRON® EC

- Highest Production Efficiency

- Shortest Processing time with minimum environmental impact

- Highest Resource Savings

- Highly recommended for 40 0C Wash fastness

- Excellent dry heat fastness

- Very good CEL reservation

- Very Good stability to reduction, leading to excellent shade reproducibility

- High fastness to multiple Home Laundering

Compared to Foundation

7.0L vs 12.9L of water

0.27kwH vs 0.47 kwH of electricity

416g vs 768g of carbon emission

Cost Calculated with 2.5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.075 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

CONTINUOUS PRETREATMENT SYSTEM

- Product selection for highest requirements in terms of water retention (absorbency) and whiteness

- Fully phosphorous-free product selection

- Bactosol HPA for flexible application (Pad Steam, immersion) and efficient starch degradation

- Prestogen SIFA for highest base whiteness in combination with OBA

- Invatex SA with excellent dispersing and heavy metal chelating power

TERASIL® W and NOVACRON® EC

- Highest Production Efficiency

- Shortest Processing time with minimum environmental impact

- Highest Resource Savings

- Highly recommended for 40 0C Wash fastness

- Excellent dry heat fastness

- Very good CEL reservation

- Very Good stability to reduction, leading to excellent shade reproducibility

- High fastness to multiple Home Laundering

Compared to Foundation

6.6L vs 12.5L of water

0.27kwH vs 0.47 kwH of electricity

408g vs 756g of carbon emission

Cost Calculated with 2.5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.075 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

CONTINUOUS PRETREATMENT SYSTEM

- Product selection for highest requirements in terms of water retention (absorbency) and whiteness

- Fully phosphorous-free product selection

- Bactosol HPA for flexible application (Pad Steam, immersion) and efficient starch degradation

- Prestogen SIFA for highest base whiteness in combination with OBA

- Invatex SA with excellent dispersing and heavy metal chelating power

TERASIL® W and NOVACRON® EC

- Highest Production Efficiency

- Shortest Processing time with minimum environmental impact

- Highest Resource Savings

- Highly recommended for 40 0C Wash fastness

- Excellent dry heat fastness

- Very good CEL reservation

- Very Good stability to reduction, leading to excellent shade reproducibility

- High fastness to multiple Home Laundering

Mill savings

By adopting a full IMPACT solution and based on the average shade mix a mill produces, a mill can achieve savings of up to:

in increased production

in water usage

in power consumption

in CO2 emissions

Based on an average plant production of 50 MT per day.

We’re sorry, but there are no results for this configuration.

We’re sorry, but there are no results for this configuration.

Features

Available Super Systems+ levels

Align your sustainability goals with your choice of SUPER SYSTEMS+

Archroma are proud members and/or partners with the following organizations