- Packaging Technologies

- /

- Process Chemicals

Process Chemicals

Enhanced fiber performance and strength

Enhanced fiber performance and strength

Process chemicals are the cornerstone of optimizing efficiency, yield, and sustainability in paper and board production. They serve to enhance fiber performance and drainage during the production process, as well as strengthening the paper itself – allowing manufacturers to produce stronger, more durable packaging while maximising the use of recycled fiber.

Our process chemical solutions help to prevent foam build-up, reduce machine downtime, improve color stability and minimize waste.

Cartastrength® – Strength enhancer

Cartastrength® is a specialty strength enhancer used to improve the physical strength and durability characteristics of paper and board in packaging applications. It is available in dry and wet strength variants, helping manufacturers to achieve higher durability and efficiency – even with increased recycled fiber content.

This solution range improves fiber bonding (reducing the need for virgin fibers), ensures that paper retains structural integrity in humid conditions and, working in tandem with retention aids like Carteretin®, can improve efficiency and yield.

Cartastrength® meets BfR & FDA food contact standards – ensuring safety in food packaging. It is also designed for easy repulping – making it a sustainable solution. Available for dry and wet strength.

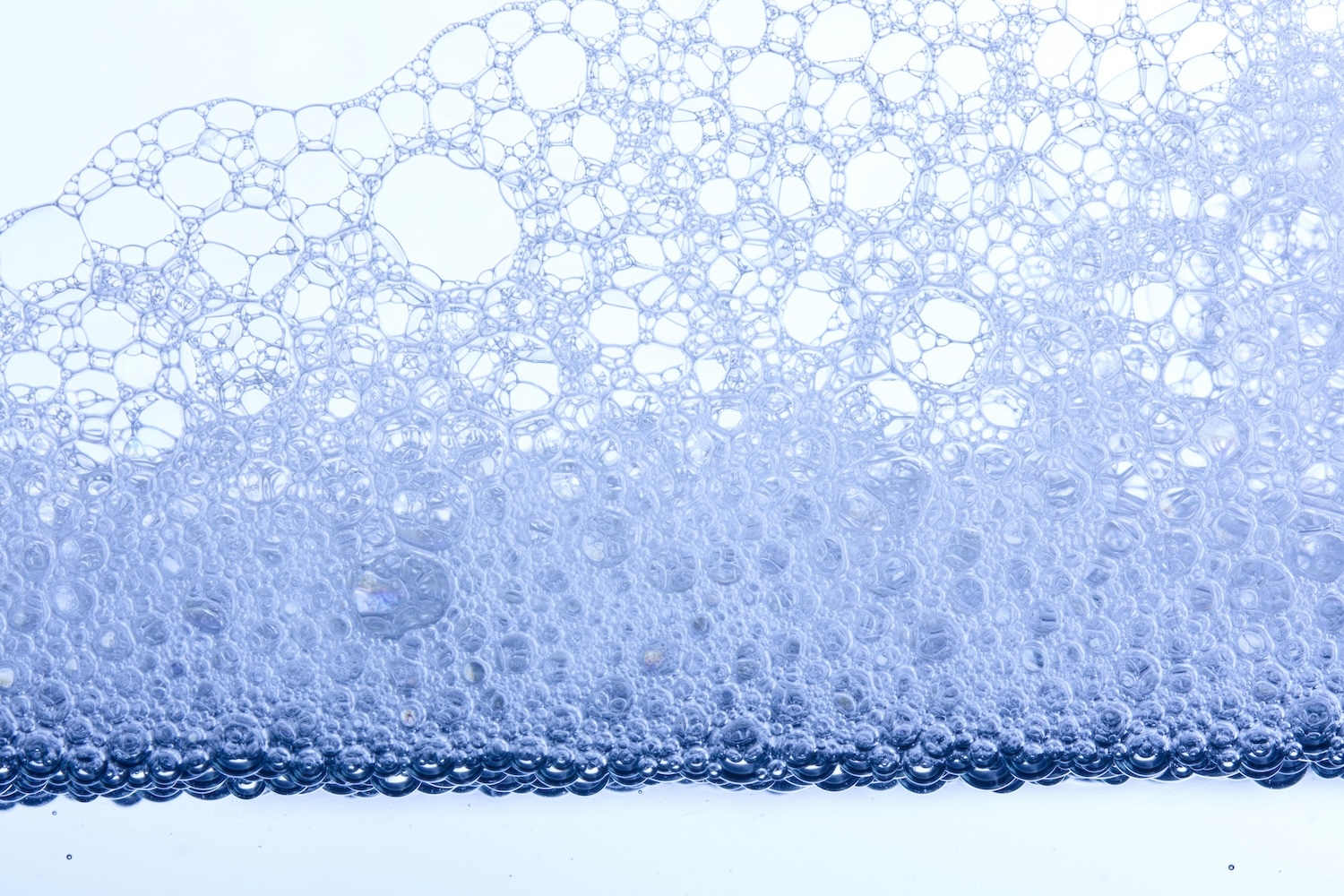

Antimussol® – Antifoam & drainage aid

Antimussol® is an antifoam emulsion developed for pulp mills. It is primarily used to control foam formation and enhance drainage efficiency during different stages of the papermaking process.

This solution is particularly effective in pulp washing and screening, as well as bleaching and sewage treatment. When applied in the paper machine process, it helps deaerate and regulate foam, improving production efficiency.

Cartafix® – Dye fixative

Cartafix® is a cationic polymer fixative, designed to improve dye fixation, reduce bleed, and enhance backwater clarity in pulp and paper production. It can improve fiber recovery and improve machine runnability due to the Anionic trash catching capabilities that improve system efficiency.

Cartafix® is particularly beneficial in ensuring brilliant, stable shades with minimal wastewater contamination.

This solution prevents color migration, ensuring long-lasting vibrancy and rapidly binds dyes to fibers, boosting dye yield and reducing chemical waste.

Cartafix® meets BfR and FDA food contact standards.

Cartaspers® – Passivation chemistry

Cartaspers PSM T30: Our unique passivation solution for machine fabrics that reduces downtime and increases operational efficiency. Keeps the machine fabrics clean in a process where recycled fiber or pitch is blocking them without a risk of chemical deposits.

Cartaspers PLH: Deposit control for virgin fiber-based pitch deposits. Organic product for passivation of pitch particles and maximizing the efficiency of hardwood pulp process or paper machine. Reduces downtime and cleaning intervals while being cost efficient vs. inorganic solutions (talcum).

Cartaspers SCS: Deposit control for recycled fiber-based stickie deposits. Passivation product for efficient stickies control at the recycled fiber plant or on a paper machine. This enables a more efficient process, minimizes downtime and reduces dusting without the risk of chemical deposits or cationic overload.

Cartaretin® – Retention & drainage aid

Cartaretin® is a high-performance cationic flocculant used in paper mills, particularly those utilizing recycled fiber. It enhances retention and drainage in paper production, improves fiber recovery in Disc Filters, and aids sludge dewatering, reducing waste. Designed for high-conductivity water circuits, it optimizes efficiency in packaging production.

Questions about our solutions?

Reach out here and will get back to you as soon as possible.

Product availability may vary by country or region. Some products may not be available in certain markets. Our team is always on-hand to help – please contact us to discuss.

Archroma are proud members and/or partners with the following organizations