- Textile Effects

- /

- SUPER SYSTEMS+

- /

- Active Wear

Active Wear

Enable soft and silky comfort, freshness and non-yellowing moisture management while also bringing the popular color-blocking effects and high whiteness that active wear fans crave. Prioritize resource savings and operational excellence. Ensure compliance with current or anticipated chemical restrictions.

Super Systems+

We believe that we can reduce the environmental impact for the planet and people by improving resource savings in manufacturing and consumer use, adopting cleaner chemistries and enhancing durability of the finishing effects and colors.

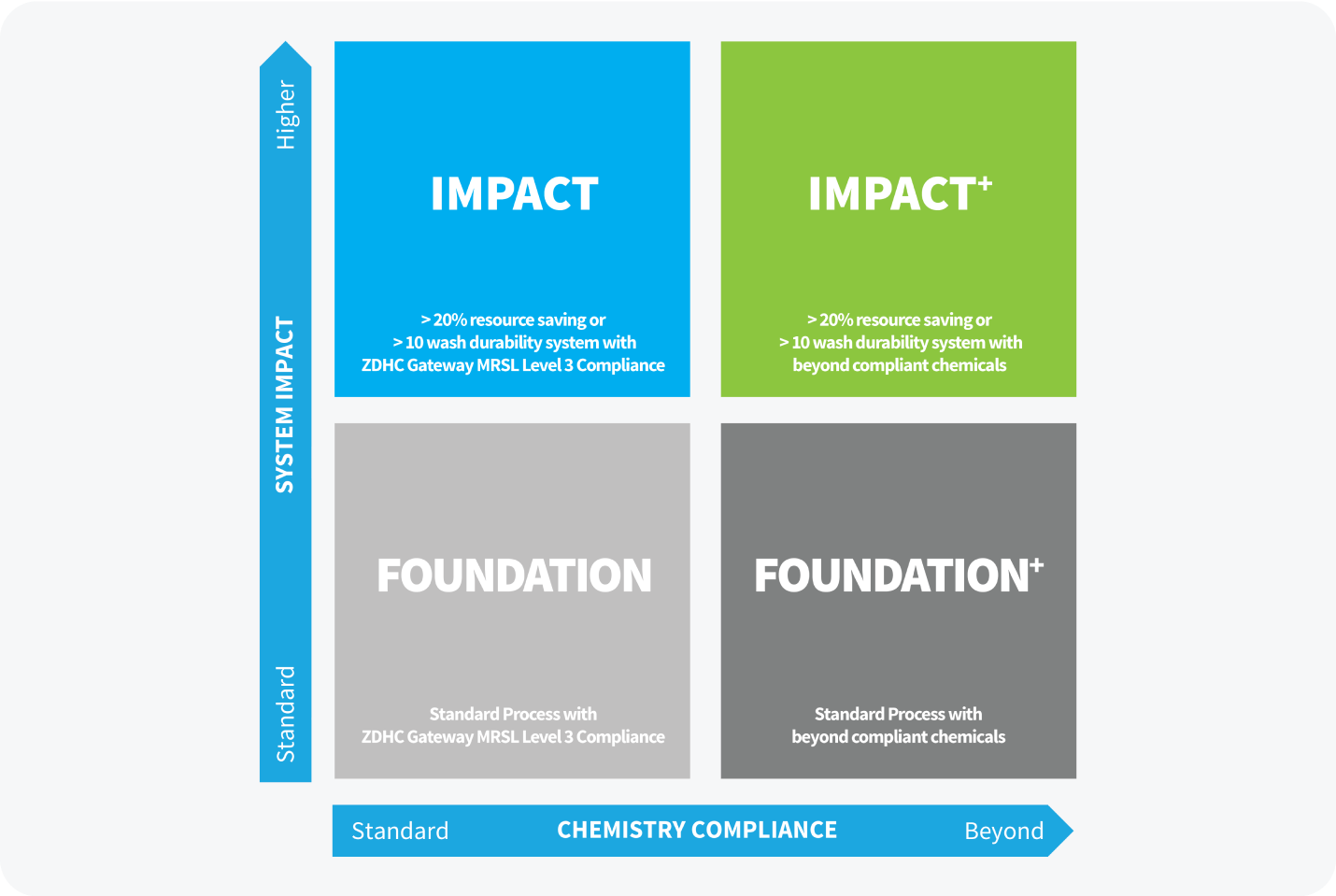

Organized into four quadrants Foundation, Foundation+, Impact and Impact+. The Impact Matrix addresses the key challenges facing the textile industry and guides you in making informed decisions about using cleaner chemistries, resource saving solutions in processing, improved durability in consumer use or a combination of all.

Our Super Systems+ is a comprehensive tool that guides you to achieve your sustainability goals without compromise.

Features

Available Super Systems+ levels

Foundation

Foundation portfolio

Solutions in the FOUNDATION portfolio meet the standard process with ZDHC Gateway MRSL Level 3 Compliance.

There are currently no solutions available for Foundation in this specific end-use. Do explore our solutions for Impact+ and Impact.

Solutions in the FOUNDATION portfolio meet the standard process with ZDHC Gateway MRSL Level 3 Compliance.

There are currently no solutions available for Foundation in this specific end-use. Do explore our solutions for Impact+ and Impact.

Impact

Garment savings

Compared to Foundation

4.8L vs 14.0L of water

0.02kwH vs 0.03 kwH of electricity

106g vs 244g of carbon emission

Cost Calculated with 5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

NYLOSAN® S

Comprehensive metal-free dyestuff range that enables mills to achieve high fastness and buildup on polyamide and nylon

NYLOFIXAN®HFS Liq

Highly efficient fixative for the aftertreatment of polyamide

Compared to Foundation

9.4L vs 14.0L of water

0.028kwH vs 0.034 kwH of electricity

184g vs 244g of carbon emission

Cost Calculated with 5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

NYLOSAN® S

Comprehensive metal-free dyestuff range that enables mills to achieve high fastness and buildup on polyamide and nylon

NYLOFIXAN® HFS Liq

Highly efficient fixative for the aftertreatment of polyamide

Foundation+

Foundation+ portfolio

Solutions in the FOUNDATION+ portfolio utilize innovative technologies to either design out hazardous or regulated substances or reduce them by more than 95% compared to the current industry standard limits. They meet the standard process with ZDHC Gateway MRSL Level 3 Compliance with beyond compliant chemicals.

There are currently no solutions available for Foundation+ in this specific end-use. Do explore our solutions for Impact+ and Impact.

Solutions in the FOUNDATION+ portfolio utilize innovative technologies to either design out hazardous or regulated substances or reduce them by more than 95% compared to the current industry standard limits. They meet the standard process with ZDHC Gateway MRSL Level 3 Compliance with beyond compliant chemicals.

There are currently no solutions available for Foundation+ in this specific end-use. Do explore our solutions for Impact+ and Impact.

Impact+

Garment savings

Compared to Foundation

10.2L vs 14.0L of water

0.03kwH vs 0.05 kwH of electricity

188g vs 270g of carbon emission

Cost Calculated with 5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

ERIOFAST®

Specially developed polyamide dye range with excellent migration, levelling and color blocking properties. Free of detectable Phenol and Bisphenol compounds

ERIOFAST® FIX-01

Crosslinking agent that improves wet fastness properties and ensures stable and reproducible shades

Compared to Foundation

10.2L vs 14.0L of water

0.04kwH vs 0.05 kwH of electricity

190g vs 270g of carbon emission

Cost Calculated with 5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

ERIOFAST®

Specially developed polyamide dye range with excellent migration, levelling and color blocking properties. Free of detectable Phenol and Bisphenol compounds

ERIOFAST® FIX-01

Crosslinking agent that improves wet fastness properties and ensures stable and reproducible shades

Features

Available Super Systems+ levels

Align your sustainability goals with your choice of SUPER SYSTEMS+

Archroma are proud members and/or partners with the following organizations