- Textile Effects

- /

- SUPER SYSTEMS+

- /

- Athletic Wear

Athletic Wear

Achieve valued effects like moisture management, freshness and UV protection, while improving soft comfort for reduced chaffing and better range of movement. Prioritize resource savings and operational excellence. Ensure compliance with current or anticipated chemical restrictions.

Super Systems+

We believe that we can reduce the environmental impact for the planet and people by improving resource savings in manufacturing and consumer use, adopting cleaner chemistries and enhancing durability of the finishing effects and colors.

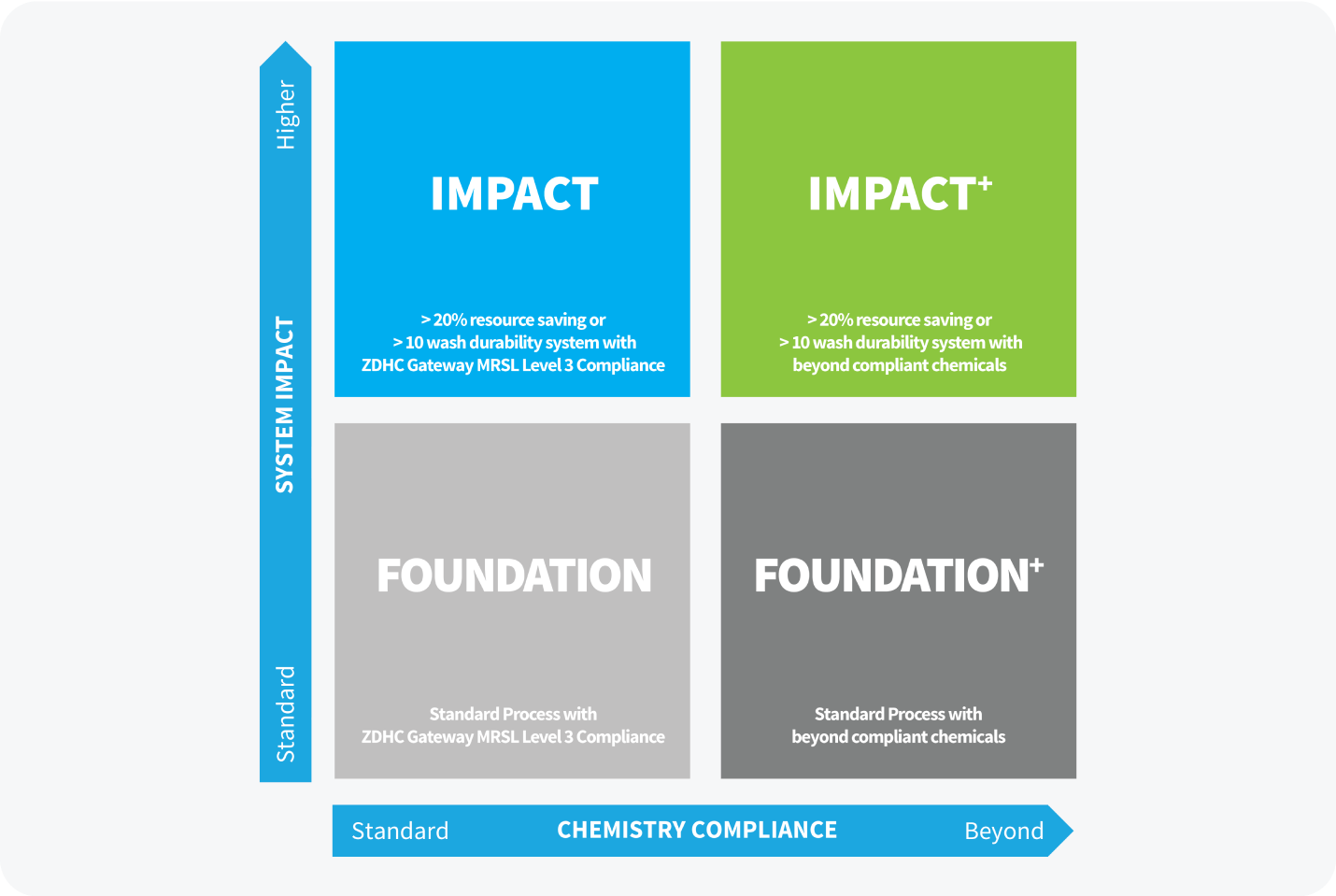

Organized into four quadrants Foundation, Foundation+, Impact and Impact+. The Impact Matrix addresses the key challenges facing the textile industry and guides you in making informed decisions about using cleaner chemistries, resource saving solutions in processing, improved durability in consumer use or a combination of all.

Our Super Systems+ is a comprehensive tool that guides you to achieve your sustainability goals without compromise.

Features

Available Super Systems+ levels

Foundation

Foundation portfolio

Solutions in the FOUNDATION portfolio meet the standard process with ZDHC Gateway MRSL Level 3 Compliance.

Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

LYOCOL® PRDN LIQ

Dispersant to maintain finest dye distribution throughout whole dyeing process, preventing contamination of the dyeing machine.

FORON® E, SE, S

Classic disperse dyes with FORON E for pale to medium, FORON SE for widest range of applications and FORON S with highest sublimation fastness.

Solutions in the FOUNDATION portfolio meet the standard process with ZDHC Gateway MRSL Level 3 Compliance.

Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

LYOCOL® PRDN LIQ

Dispersant to maintain finest dye distribution throughout whole dyeing process, preventing contamination of the dyeing machine.

FORON® E, SE, S

Classic disperse dyes with FORON E for pale to medium, FORON SE for widest range of applications and FORON S with highest sublimation fastness.

Solutions in the FOUNDATION portfolio meet the standard process with ZDHC Gateway MRSL Level 3 Compliance.

Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

LYOCOL® PRDN LIQ

Dispersant to maintain finest dye distribution throughout whole dyeing process, preventing contamination of the dyeing machine.

FORON® E, SE, S

Classic disperse dyes with FORON E for pale to medium, FORON SE for widest range of applications and FORON S with highest sublimation fastness.

Impact

Garment savings

Compared to Foundation

5.2L vs 6.2L of water

0.05kwH vs 0.06 kwH of electricity

154g vs 192g of carbon emission

Cost Calculated with 5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

HUMECTOL® X-SD Liq

Universal lubricating agent with very good emulsifying properties, low foaming properties and improves running properties. Reduces the yellowing of spinning preparation during thermofixation of synthetic fibers and blends with elastane.

TERASIL® W

Wash fast disperse dyes for polyester and polyester blends with excellent washfastness and robustness.

Compared to Foundation

5.2L vs 6.2L of water

0.05kwH vs 0.06 kwH of electricity

154g vs 192g of carbon emission

Cost Calculated with 5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

HUMECTOL® X-SD Liq

Universal lubricating agent with very good emulsifying properties, low foaming properties and improves running properties. Reduces the yellowing of spinning preparation during thermofixation of synthetic fibers and blends with elastane.

TERASIL® W

Wash fast disperse dyes for polyester and polyester blends with excellent washfastness and robustness.

Compared to Foundation

0.028kwH vs 0.030 kwH of electricity

76g vs 90g of carbon emission

Cost Calculated with 5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

ULTRAVON® ROS

Low foaming wetting agent and detergent with outstanding emulsifying and degreasing power for continuous, semi-continuous and discontinuous processes.

ULTRAPHOR® ETB Liq

Outstanding neutral bluish white effect that is suitable for both Exhaust and Thermosol process with excellent fastness properties.

Mill savings

By adopting a full IMPACT solution and based on the average shade mix a mill produces, a mill can achieve savings of up to:

in increased production

in water usage

in power consumption

in CO2 emissions

Based on an average plant production of 50 MT per day.

Foundation+

Foundation+ portfolio

Solutions in the FOUNDATION+ portfolio utilize innovative technologies to either design out hazardous or regulated substances or reduce them by more than 95% compared to the current industry standard limits. They meet the standard process with ZDHC Gateway MRSL Level 3 Compliance with beyond compliant chemicals.

There are currently no solutions available for Foundation+ for this specific end-use. Do explore our solutions for Impact+ and Impact.

Solutions in the FOUNDATION+ portfolio utilize innovative technologies to either design out hazardous or regulated substances or reduce them by more than 95% compared to the current industry standard limits. They meet the standard process with ZDHC Gateway MRSL Level 3 Compliance with beyond compliant chemicals.

There are currently no solutions available for Foundation+ for this specific end-use. Do explore our solutions for Impact+ and Impact.

Solutions in the FOUNDATION+ portfolio utilize innovative technologies to either design out hazardous or regulated substances or reduce them by more than 95% compared to the current industry standard limits. They meet the standard process with ZDHC Gateway MRSL Level 3 Compliance with beyond compliant chemicals.

There are currently no solutions available for Foundation+ for this specific end-use. Do explore our solutions for Impact+ and Impact.

Impact+

Garment savings

Compared to Foundation

4.2L vs 6.2L of water

0.04kwH vs 0.06 kwH of electricity

130g vs 192g of carbon emission

Cost Calculated with 5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

ERIOPON® E3-SAVE

Reliable pretreatment system for absorbency, whiteness and fiber protection from chemical damage

TERASIL® WW

High performance washfast dyes for polyester that offer outstanding washfastness with outstanding right-first-time results to meet the most stringent brand requirements

Compared to Foundation

4.2L vs 6.2L of water

0.04kwH vs 0.06 kwH of electricity

130g vs 192g of carbon emission

Cost Calculated with 5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

ERIOPON® E3-SAVE

Advanced all-in-one wet processing agent for polyester fibers that shortens the dyeing process significantly

TERASIL® WW

High performance washfast dyes for polyester that offer outstanding washfastness with outstanding right-first-time results to meet the most stringent brand requirements

Compared to Foundation

0.028kwH vs 0.030 kwH of electricity

76g vs 90g of carbon emission

Cost Calculated with 5 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

KIERALON® F-MFB

A multifunctional low foaming surfactant for silicon preparations and removal of mineral deposits

UVITEX® EEDB

Versatile fluorescent whitening agent with slightly bluish-violet white shade. Provides excellent fastness for polyester fibers and their blends in all stages of processing.

Mill savings

By adopting a full IMPACT+ solution and based on the average shade mix a mill produces, a mill can achieve savings of up to:

in increased production

in water usage

in power consumption

in CO2 emissions

Based on an average plant production of 50 MT per day.

Features

Available Super Systems+ levels

Align your sustainability goals with your choice of SUPER SYSTEMS+

Archroma are proud members and/or partners with the following organizations