- Textile Effects

- /

- SUPER SYSTEMS+

- /

- Cotton Knits

Cotton Knits

Achieve valued effects like lasting colors, exceptional comfort and enduring freshness. You can also prioritize resource savings and operational excellence, while ensuring compliance with current or anticipated chemical restrictions.

Super Systems+

We believe that we can reduce the environmental impact for the planet and people by improving resource savings in manufacturing and consumer use, adopting cleaner chemistries and enhancing durability of the finishing effects and colors.

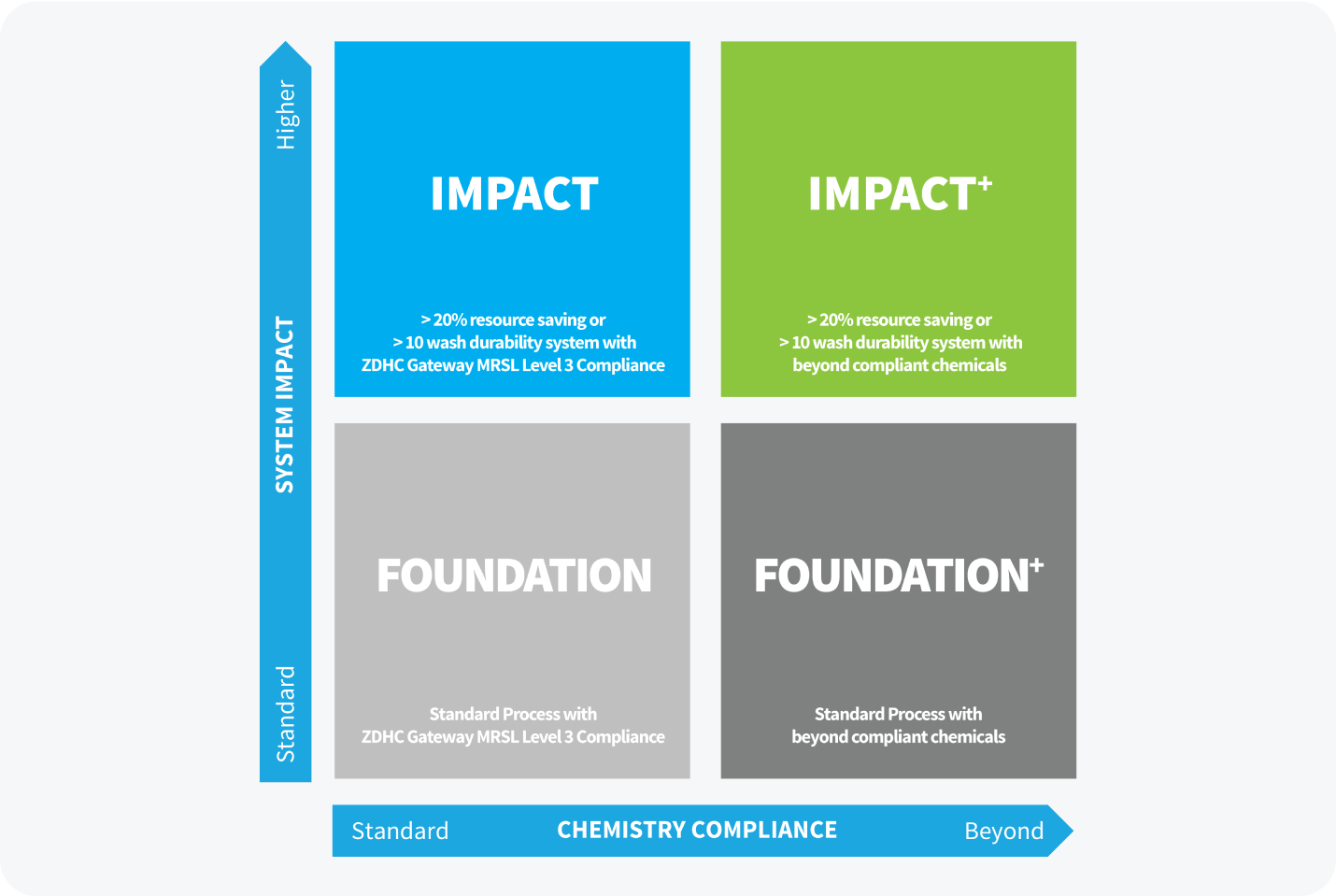

Organized into four quadrants Foundation, Foundation+, Impact and Impact+. The Impact Matrix addresses the key challenges facing the textile industry and guides you in making informed decisions about using cleaner chemistries, resource saving solutions in processing, improved durability in consumer use or a combination of all.

Our Super Systems+ is a comprehensive tool that guides you to achieve your sustainability goals without compromise.

Features

Available Super Systems+ levels

Foundation

Foundation portfolio

Solutions in the FOUNDATION portfolio meet the standard process with ZDHC Gateway MRSL Level 3 Compliance.

CLARITE® ONE / IMEROL® PCLF

Low foaming and high-performance emulsifying agent, together with efficient, ecological and economical all-in-one pretreatment solution for peroxide bleaching processes on cellulosic fibers and their blends.

NOVACRON® BOLD / DRIMAREN® CL

A balanced cost performance, especially for navy and black, with industry standard fastness properties. Highly efficient multi-purpose dyeing auxiliary system.

Solutions in the FOUNDATION portfolio meet the standard process with ZDHC Gateway MRSL Level 3 Compliance.

CLARITE® ONE / IMEROL® PCLF

Low foaming and high-performance emulsifying agent, together with efficient, ecological and economical all-in-one pretreatment solution for peroxide bleaching processes on cellulosic fibers and their blends.

NOVACRON® BOLD / DRIMAREN® CL

A balanced cost performance, especially for navy and black, with industry standard fastness properties. Highly efficient multi-purpose dyeing auxiliary system.

Solutions in the FOUNDATION portfolio meet the standard process with ZDHC Gateway MRSL Level 3 Compliance.

CLARITE® ONE / IMEROL® PCLF

Low foaming and high-performance emulsifying agent, together with efficient, ecological and economical all-in-one pretreatment solution for peroxide bleaching processes on cellulosic fibers and their blends.

NOVACRON® EC / HF

Complete range of reactive dyes that offer superior operational excellence especially in pale shades and fastness properties meet stringent brand specifications

Solutions in the FOUNDATION portfolio meet the standard process with ZDHC Gateway MRSL Level 3 Compliance.

CLARITE® ONE / IMEROL® PCLF

Low foaming and high-performance emulsifying agent, together with efficient, ecological and economical all-in-one pretreatment solution for peroxide bleaching processes on cellulosic fibers and their blends.

NOVACRON® EC / HF

Complete range of reactive dyes that offer superior operational excellence especially in pale shades and fastness properties meet stringent brand specifications

Solutions in the FOUNDATION portfolio meet the standard process with ZDHC Gateway MRSL Level 3 Compliance.

CLARITE® ONE

Efficient, ecological and economical all-in-one pretreatment solution for peroxide bleaching processes on cellulosic fibers and their blends.

UVITEX® BME LIQ / LEUCOPHOR® BMB

Versatile fluorescent whitening agent with neutral bluish white shade. Provides optimal fastness levels on cellulosic fibers.

Impact

Garment savings

Compared to Foundation

10.6L vs 15.5L of water

0.12kwH vs 0.17 kwH of electricity

290g vs 423g of carbon emission

Cost Calculated with 3 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

SCOUR DYE with KIERALON® UH LIQ

Sustainable pretreatment solution for creating durable dark colors on cotton on without utilizing massive amounts of water and energy compared to conventional benchmark processes.

NOVACRON® EC/S

Complete range of reactive dyes that offer superior operational excellence especially in pale shades and meet stringent brand specifications for fastness requirements

CYCLANON® XCW

High performance soaping agent that helps mills achieve greater productivity with reduced costs

Compared to Foundation

11.8L vs 16.0L of water

0.14kwH vs 0.17 kwH of electricity

330g vs 433g of carbon emission

Cost Calculated with 3 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

Blue Magic

All-in-one pretreatment that delivers both economic and ecological advantages

NOVACRON® EC/S

Complete range of reactive dyes that offer superior operational excellence especially in pale shades and meet stringent brand specifications for fastness requirements

CYCLANON® XCW

High performance soaping agent that helps mills achieve greater productivity with reduced costs

Compared to Foundation

10.6L vs 13.0L of water

0.13kwH vs 0.14 kwH of electricity

313g vs 353g of carbon emission

Cost Calculated with 3 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

Blue Magic

All-in-one pretreatment that delivers both economic and ecological advantages

NOVACRON® EC/S

Complete range of reactive dyes that offer superior operational excellence especially in pale shades and meet stringent brand specifications for fastness requirements

CYCLANON® XCW

High performance soaping agent that helps mills achieve greater productivity with reduced costs

Compared to Foundation

10.6L vs 11.8L of water

0.13kwH vs 0.14 kwH of electricity

297g vs 337g of carbon emission

Cost Calculated with 3 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

Blue Magic

All-in-one pretreatment that delivers both economic and ecological advantages

NOVACRON® EC/S

Complete range of reactive dyes that offer superior operational excellence especially in pale shades and meet stringent brand specifications for fastness requirements

CYCLANON® XCW

High performance soaping agent that helps mills achieve greater productivity with reduced costs

Compared to Foundation

3.3L vs 4.5L of water

0.07kwH vs 0.08 kwH of electricity

197g vs 230g of carbon emission

Cost Calculated with 3 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

Blue Magic

All-in-one pretreatment that delivers both economic and ecological advantages

UVITEX BHT® LIQ 115%

Versatile fluorescent whitening agent with slightly bluish-white shade.

Mill savings

By adopting a full IMPACT solution and based on the average shade mix a mill produces, a mill can achieve savings of up to:

in increased production

in water usage

in power consumption

in CO2 emissions

Based on an average plant production of 50 MT per day.

Foundation+

Foundation+ portfolio

Solutions in the FOUNDATION+ portfolio utilize innovative technologies to either design out hazardous or regulated substances or reduce them by more than 95% compared to the current industry standard limits. They meet the standard process with ZDHC Gateway MRSL Level 3 Compliance with beyond compliant chemicals.

There are currently no solutions available for Foundation+. Do explore our solutions for Impact+ and Impact.

Solutions in the FOUNDATION+ portfolio utilize innovative technologies to either design out hazardous or regulated substances or reduce them by more than 95% compared to the current industry standard limits. They meet the standard process with ZDHC Gateway MRSL Level 3 Compliance with beyond compliant chemicals.

There are currently no solutions available for Foundation+. Do explore our solutions for Impact+ and Impact.

Solutions in the FOUNDATION+ portfolio utilize innovative technologies to either design out hazardous or regulated substances or reduce them by more than 95% compared to the current industry standard limits. They meet the standard process with ZDHC Gateway MRSL Level 3 Compliance with beyond compliant chemicals.

There are currently no solutions available for Foundation+. Do explore our solutions for Impact+ and Impact.

Solutions in the FOUNDATION+ portfolio utilize innovative technologies to either design out hazardous or regulated substances or reduce them by more than 95% compared to the current industry standard limits. They meet the standard process with ZDHC Gateway MRSL Level 3 Compliance with beyond compliant chemicals.

There are currently no solutions available for Foundation+. Do explore our solutions for Impact+ and Impact.

Solutions in the FOUNDATION+ portfolio utilize innovative technologies to either design out hazardous or regulated substances or reduce them by more than 95% compared to the current industry standard limits. They meet the standard process with ZDHC Gateway MRSL Level 3 Compliance with beyond compliant chemicals.

There are currently no solutions available for Foundation+. Do explore our solutions for Impact+ and Impact.

Impact+

Garment savings

Compared to Foundation

9.5L vs 15.5L of water

0.11kwH vs 0.17 kwH of electricity

263g vs 423g of carbon emission

Cost Calculated with 3 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

SCOUR DYE with KIERALON® UH Liq.

Sustainable pretreatment solution for creating durable dark colors on cotton without utilizing massive amounts of water and energy compared to conventional benchmark processes.

AVITERA® SE

A revolutionary breakthrough in the dyeing of cellulosic fibers and its blends.

Compared to Foundation

9.5L vs 16.0L of water

0.13kwH vs 0.17 kwH of electricity

277g vs 433g of carbon emission

Cost Calculated with 3 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

Blue Magic

All-in-one pretreatment that delivers both economic and ecological advantages

AVITERA® SE

A revolutionary breakthrough in the dyeing of cellulosic fibers and its blends

Compared to Foundation

9.5L vs 13.0L of water

0.12kwH vs 0.14 kwH of electricity

273g vs 353g of carbon emission

Cost Calculated with 3 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

Blue Magic

All-in-one pretreatment that delivers both economic and ecological advantages

AVITERA® SE

A revolutionary breakthrough in the dyeing of cellulosic fibers and its blends

Compared to Foundation

8.3L vs 11.8L of water

0.12kwH vs 0.14 kwH of electricity

263g vs 337g of carbon emission

Cost Calculated with 3 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

Blue Magic

All-in-one pretreatment that delivers both economic and ecological advantages

AVITERA® SE

A revolutionary breakthrough in the dyeing of cellulosic fibers and its blends

Compared to Foundation

3.3L vs 4.5L of water

0.07kwH vs 0.08 kwH of electricity

197g vs 230g of carbon emission

Cost Calculated with 3 Garments per Kg Fabric, Total Cost = Pretreatment Cost + Dyestuff Cost + DA and Wash Off Cost+ Utility Cost + Fix Cost Utility Cost Considered : Electricity Cost 0.0875 USD/kWh, Water Cost 1.0 USD/KL, Steam Cost 0.0219 USD/Kg, Fix Cost 0.0375 USD/Kg/hour Operational Excellence: Cost of Non-Conformance considered in foundation due to reduced Right First Time levels

Blue Magic

All-in-one pretreatment that delivers both economic and ecological advantages

UVITEX® BHA

Aniline-free, high-affinity brightening range for textiles and with high bath exhaustion and low wastewater pollution

Mill savings

By adopting a full IMPACT+ solution and based on the average shade mix a mill produces, a mill can achieve savings of up to:

in increased production

in water usage

in power consumption

in CO2 emissions

Based on an average plant production of 50 MT per day.

Features

Available Super Systems+ levels

Align your sustainability goals with your choice of SUPER SYSTEMS+

Archroma are proud members and/or partners with the following organizations